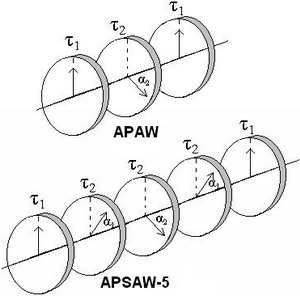

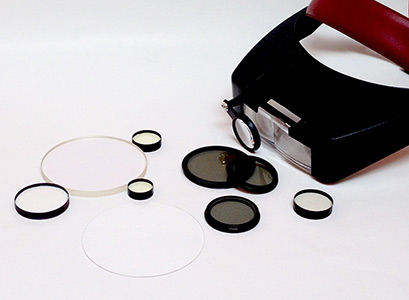

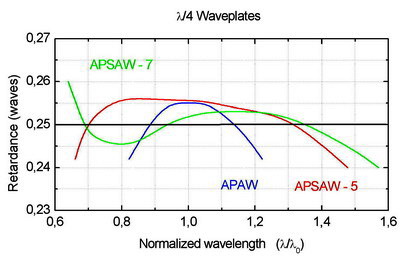

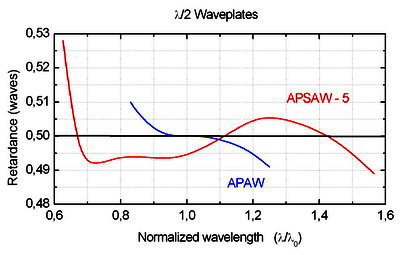

Achromatic (APAW) and Super-Achromatic (APSAW) True Zero-Order Quarter and Half Waveplates are constructed using a stack of birefringent polymer plates cemented between two glass windows, each with a broadband antireflection coating. APAW consist of three polymer plates, APSAW-5 consist of five polymer plates, APSAW-7 consist of seven polymer plates that provide more wide spectral range of achromatization. Retardation of each polymer plate does not exceed λ/2 (180°) in the zero order. Optical axes of all plates are oriented relative to one another in a specific way. This construction operates with a high degree of retardation accuracy over a broad wavelength range, ensures excellent transmitted wavefront quality, while minimizing beam deviation and surface reflection losses. The construction ensures clear acceptance > 90% at outer diameter from 15 to 60 mm. APAW and APSAW are true zero-order retarders indeed. They have better angular acceptance and less sensitivity to wavelength and temperature change than achromatic quartz-MgF₂ waveplates. Optical transmittance of APSAW is not distorted by multibeam interference since each plate is produced of the same polymer material.

| Retarder Material | Birefringence polymer plate stack |

|---|---|

| Substrate Material | Fine annealed optical glass |

| Retardation | λ/4, λ/2, λ/2.83 (90° , 180° , 127°) |

| Retardation Accuracy | ± λ/100, ± λ/200, ± λ/300 |

| Wavefront deformation | < λ/4 per cm at 632.8 nm |

| Surface Quality | 40 – 20 scratch – dig |

| Beam Deviation | < 5 arcsec |

| Temperature Range | -20 °C to +50 °C |

| Antireflection Coating | Broadband, MgF₂ coating, R < 2% per surface |

| Outer Diameter | 15, 20, 25, 30, 40, 50, 60, 70 mm |

| Clear Aperture | > 90% of Outer Diameter |

| Damage Threshold | 500 W/sm² CW |

| Cleaning | Ethanol, acetone |

Achromatic and Super-Achromatic True Zero-Order waveplates with any retardance in the range 0 to λ/2 can be manufactured by special order.